Adaptive devices designed to overcome physical limitations have been part of the human existence for as long as people have roamed the earth. Moreover, technology has always been a part of developing such devices. So it should be no surprise that technology continues driving adaptive device development in the 21st century. Not leveraging available technology would make no sense.

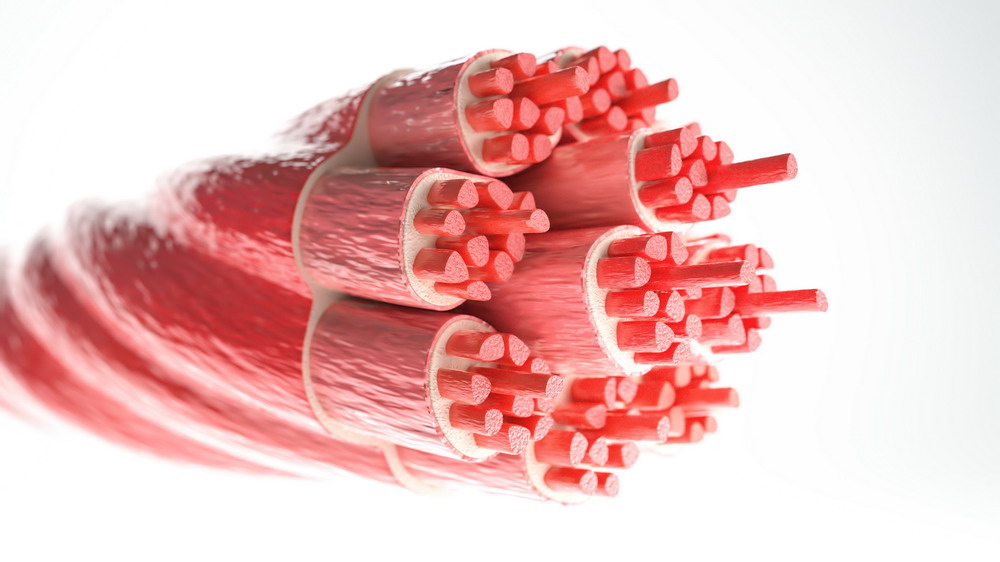

One of the more exciting examples of adaptive device technology is the carbon fiber muscle. In development for the last several years, the artificial muscle adds tremendous capability to certain kinds of adaptive devices meant to replace lost limbs. Artificial muscles restore function while simultaneously making adaptive devices feel and behave more naturally.

So, what is a carbon fiber muscle? Keep reading to find out. Suffice it to say carbon fiber muscles are an amazing piece of kit destined to change lives around the world.

Artificial Muscles with Tremendous Strength

A discussion of carbon fiber muscles begins with the more general topic of artificial muscles. An artificial muscle is a synthetic component that can do for a soft robot or prosthesis what real muscles can do for humans. It can exert force to push, pull, lift, bend, or twist.

The earliest artificial muscles were made of nylon. Engineers combined multiple nylon threads to create a coil flexible enough to expand and contract. The coils behaved a lot like bungee cords. And while first generation muscles were fairly strong, they were not strong enough to be of practical use for adaptive devices.

To overcome the limitations, researchers began looking at other materials. Artificial muscles have undergone several iterations in the years since. Today, carbon fiber is an emerging material choice. It is the strongest material artificial muscle designers have used to date. A properly designed carbon fiber muscle is so strong that it can lift 12,000 times its own weight.

The Carbon Fiber-Rubber Hybrid

By now, you might be a little confused as to how carbon fiber can be fabricated into an artificial muscle. After all, your experience with carbon fiber products involves rigid items like tennis rackets and golf clubs. Well, the answer to your confusion is a combination of carbon fiber thread and rubber.

If you were to approach a company like Salt Lake City’s Rock West Composites in search of carbon fiber tubing for a bike frame, they would offer you several different kinds of rigid tubing to choose from. The tubing is created by winding carbon fiber thread around a tool, impregnating the thread with an epoxy resin, and then curing the material to create a strong and rigid part.

This sort of thing obviously doesn’t work for artificial muscles. To replicate muscle action, you need a soft and flexible material. So, designers combined carbon fiber threads with PDMS rubber and twisted the two materials together into a coil. They bonded materials with a resin that remains flexible even after curing.

Flexing the Muscles

The truly fascinating part of artificial muscles is that they can be forced to flex on their own. All it takes is a bit of electricity. By applying just a slight electric current to either end of a carbon fiber muscle, you generate heat that affects the rubber component. As the rubber responds, it pushes the carbon fibers apart and subsequently causes the muscle to expand. Cut off the current and the muscle retracts.

Science has come up with some truly amazing ways to use carbon fiber. And now that researchers are looking at medical applications, a lot of great things are happening in the adaptive device arena.