CNC services are an industry that doesn’t have a huge load of exposure when it comes to outsiders having insider knowledge about how things work. This means that a lot of people make assumptions, fill in blanks, or are not aware of the industry almost entirely.

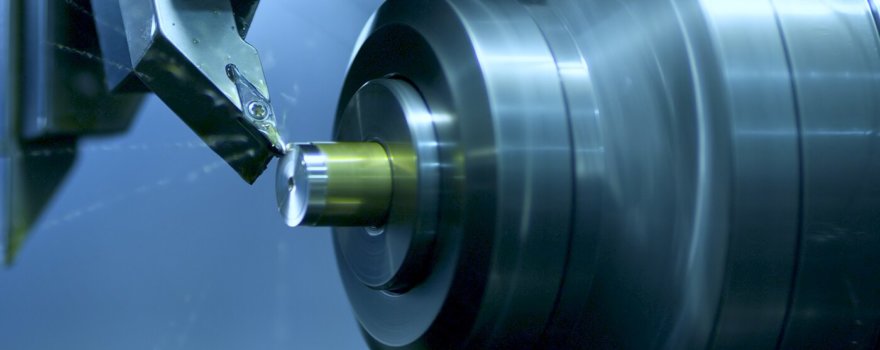

CNC machining involves carrying out tasks like drilling, boring and cutting under the instructions of a computer. With CNC, the machines make a set of instructions and specifications out of computer files and turns a piece of metal into a finished product by refining and cutting based on the instructions. It is a fast, repeatable, and efficient model that uses CNC controllers to perform complex cuts that would be too time consuming were it to be done manually. Businesses and individuals that do not possess precise machining tools and do not have repeatable parts production capabilities can save on time as well as money by utilizing CNC services.

In this article, we are going to go through a 7-point rundown of a few things you should absolutely know about CNC services as they affect your industry or area of work.

- Types of CNC machines: CNC machines come in different shapes and sizes and selection is based on the kind of work to be done (drilling, cutting, molding etc.). Some examples of popularly used CNC machines include drills, lathes, and milling machines. Aside from these, electrical/chemical machining employs techniques like electron beam machining, Electrochemical machining, Electrical Discharge Machining (EDM) and more- usually with particular kinds of materials.

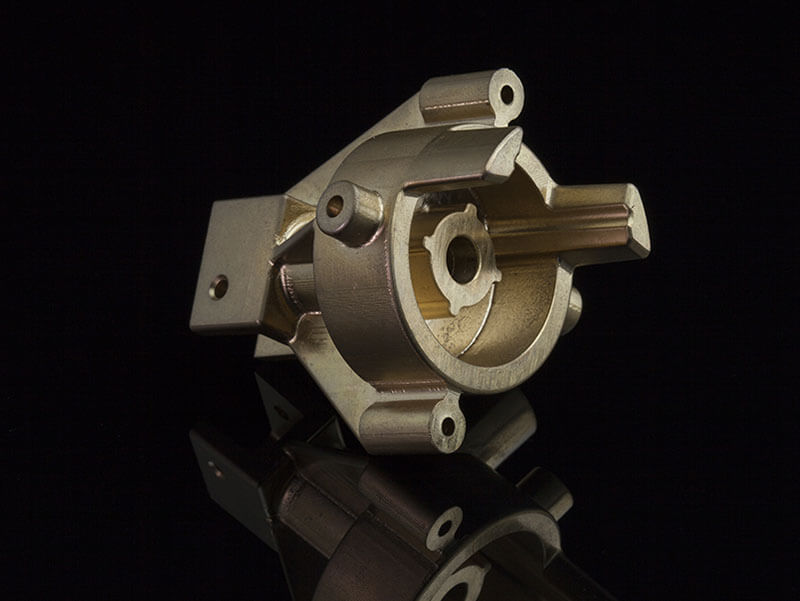

- Materials used: Almost any material can be worked on by a CNC machine. All it depends on is the application for which the finished product is intended. Metals include aluminum, brass, copper, steel, titanium, wood, foam, fiberglass, as well as different plastic materials. There is often waste produced, so CNC systems require the addition of a dust collection system to remove waste effectively, so it doesn’t disturb the process.

- Rapid, real-time prototyping: CNC services and CNC in general provided the first breakthrough in the field of rapid prototyping. Before computer numerical control, parts had to be machined by hand and this was both a slower as well as a more inefficient process. There were exponentially wider margins for error as well as defects. CNC methods are quick, labor efficient, repeatable, consistent, and high quality.

- CNC or 3D printing: Relative to how quickly things move in tech years, this seems like an age old question. There is no clear-cut answer as it depends- on the materials in question, the complexity of the part, as well as the budget and financial wherewithal of the individual or company. FDM or conventional 3D printing methods can manipulate and create complex shapes more easily than a CNC machine. However it is limited by materials and this plays to the strengths of CNC machining.

- Application in manufacturing and parts industries: A bulk of the applications of CNC machines, software, and personnel are channeled straight towards the manufacturing industries like those for vehicles, trucks, large equipment, heavy machinery, agro implements, and things of the sort. Aside from these of course, spare parts for these same industries also collect a large swathe of the share of raw materials.

- Barrier of entry: There is little barrier to entry into the business outside of the financial ones. If you have industry experience, setting up your own shop is not only possible, it is a viable idea.

- Clients: Always work to keep your clients happy. Happy, satisfied customers will always return- or at least refer you to their friends. If you are looking to break into the industry, put your clientele base first.