Creating an electronic product is a difficult task. Not only does it need to function well, but it also has to follow industry standards. Trying to handle all the various stages of development alone, for a single company, can be extremely costly. Also, it will probably take longer for the whole process to be completed without any external help. It explains why so many electronic product creators collaborate with an electronic manufacturing services provider, in order to ensure the highest quality of their products and the lowest cost possible.

Respecting the Various Creation and Production Steps

You can’t come up with an electronic product of high quality without taking the time to go through all of the steps that it takes to create and produce it. From the moment that an idea is created, a product designer will need to be involved, in order to project what the object will look like. Not all concepts turn out to be functional, as many end-up impossible to use. However, there usually are solutions to every problem a company may have with the design of its novelty. That is why they turn to an electronics manufacturing services provider (EMS) to benefit from their expertise, when they need to modify their product and raise its quality.

The sooner they are involved in the process, the better. They can start collaborating even when the project is just a simple idea. In this case, they will be able to suggest the best ways to incorporate the electronic components inside the object. This will ease the process and will raise the potential for success, when the first prototype will be created, which is the next step in line. Once it is completed, testing will need to be made on it, in order to validate the functionality of the product. If it all goes well, the EMS will be able to move on to the certification phase, before launching the production.

Elements to focus On

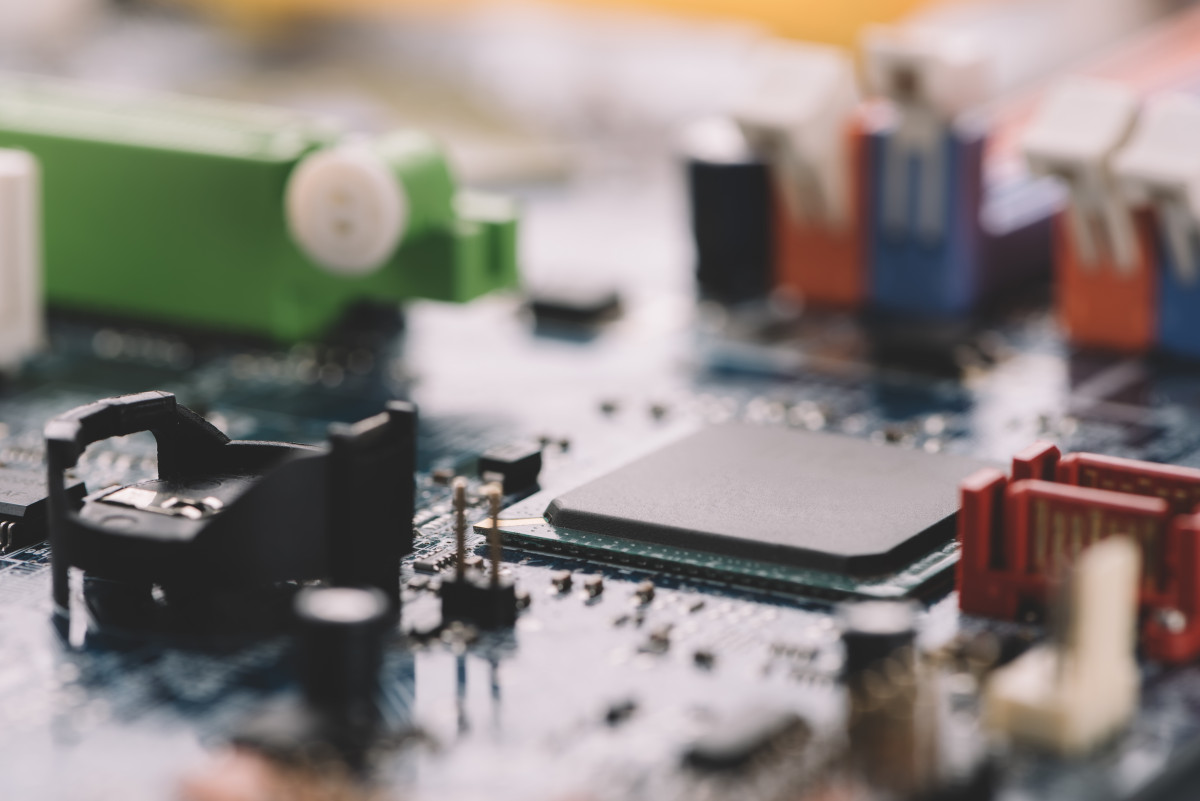

There are many things that need to be taken in account when a company aims to create and launch a new electronic product of high quality. The first is the selection of the components that it will include. The easy solution to this task is to look for the ones that comply with industry standards. This way, it is almost impossible to make a wrong choice. However, having the right components doesn’t necessarily means that the product will work as it should. That is why testing should be done until full functionality is achieved.

When a company works with an EMS provider, it needs to remain attentive every step of the way. The first thing they need to verify is that they are following the design guidelines laid out and the industry standards. All quality control checks throughout the manufacturing process must be verified to ensure that the electronic components are functioning. Testing the products regularly, as they come out of the production chain, is also a must.