Imagine a world where you can create toys, jewelry, car parts, or even a house with just a digital design. Thanks to 3D Printing service providers, you can bring your literal vision to reality using a 3D printer that transforms digital designs into physical objects. 3D printing services are companies that offer a range of 3D printing-related services, such as:

- Printing 3D models or prototypes

- Designing and creating custom 3D models

- Repairing and maintaining 3D printers

- Providing 3D scanning services

Which 3D Printing Services Can You Get?

Some of the main 3D Printing services offered commercially include:

Selective Laser Sintering (SLS)

SLS is a 3D printing technique that uses a laser to melt and fuse powdered materials to create a 3D object. This technique is often used with nylon, plastic, and metal.

It is used in various applications, including aerospace, automotive, and medical industries. For example, SLS is used to create parts for airplanes, such as air ducts, brackets, and housings. In the medical industry, SLS is used to create implants and prosthetics.

Stereolithography (SLA)

Stereolithography (SLA) is a technique that uses a liquid resin that hardens when exposed to a light source, typically a laser. The laser is directed at the resin to create a solid object, layer by layer. SLA is often used with materials like photopolymers, which can create high-resolution objects.

SLA is used in various applications, including jewelry making, dental and medical industries, and product design.

Fused Deposition Modelling (FDM)

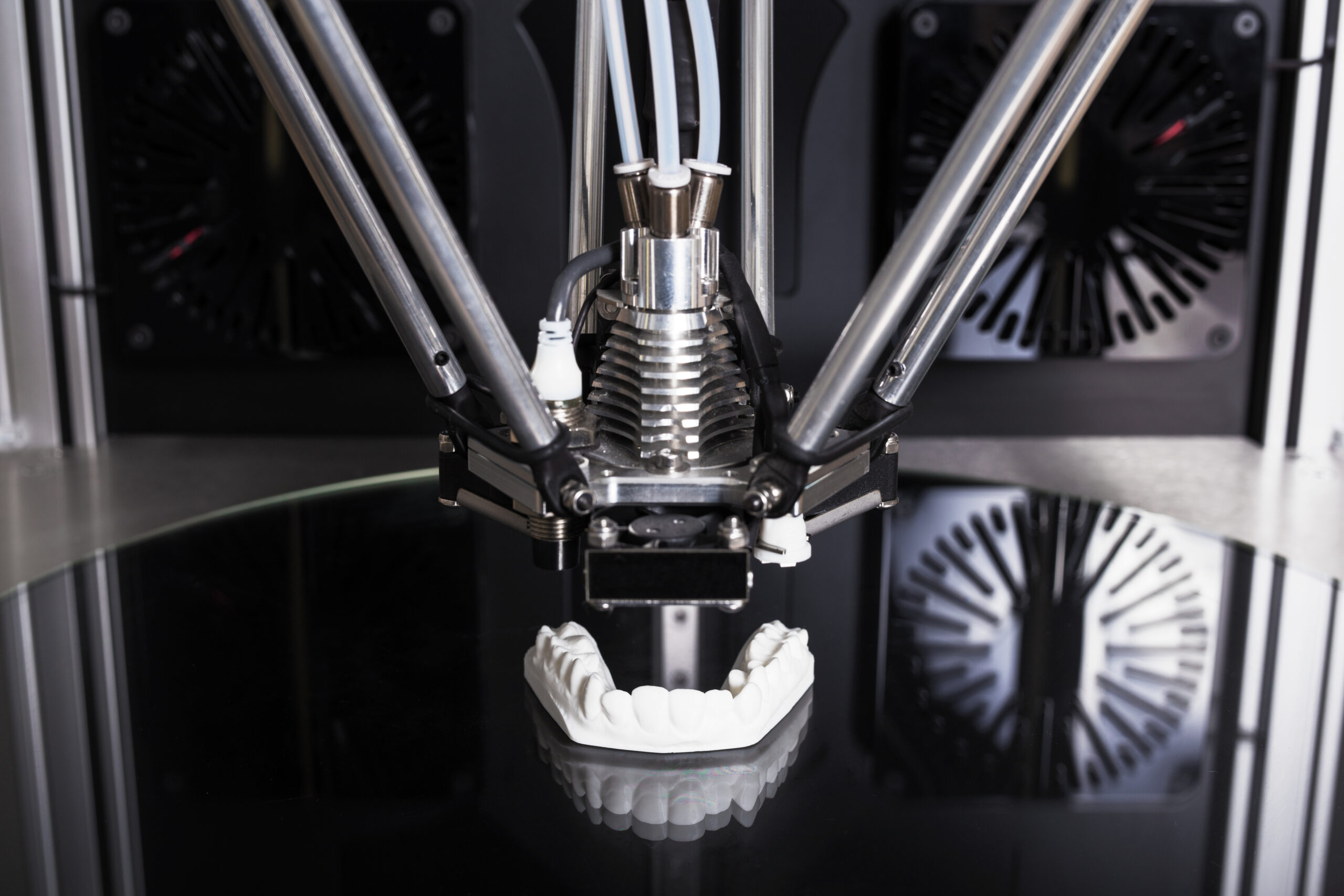

Fused Deposition Modelling (FDM) uses a heated nozzle to melt a thermoplastic material and deposit it layer by layer to create a 3D object. The nozzle moves back and forth to create the layers of the object.

FDM is a common type of 3D Printing used in product design, education, and hobbyist projects. It is used to create prototypes of new products, toys, and figurines.

Multi-Jet Fusion (MJF)

Multi-Jet Fusion (MJF) uses an inkjet array to deposit a fusing agent onto a bed of powdered material, layer by layer. The material is then exposed to an energy source that fuses the powder into a solid object.

MJF is often used with materials like nylon and is known for its high accuracy and speed. MJF is used in product design, automotive and aerospace industries, and medical industries. For example, MJF can be used to create custom car parts, surgical tools, and prosthetics.

Why You Should Use a 3D Printing Service

Whether you’re a designer, engineer, educator, or just someone interested in the latest technology trends, 3D Printing has something for everyone. 3D printing services offer numerous benefits, including:

- Faster production – 3D Printing can produce objects much faster than traditional manufacturing methods, which can take a long time to set up and produce large quantities of products.

- Customization – Just like personal 3D Printing, commercial 3D Printing allows for a high degree of customization, enabling businesses to create unique products tailored to specific customers or markets.

- Lower costs – Objects are printed on demand, so there is no need for expensive molds or tooling, which can be a significant expense with traditional manufacturing methods.

- Reduced waste – Because objects are printed on demand, there is less need for excess inventory or overproduction, which can result in wasted materials and resources.

- Innovation – Because it allows for more customization and faster prototyping, businesses can test new ideas and designs quickly and easily, leading to more innovative products and processes.

Finding the Right 3D Printing Service

With so many 3D printing options available, knowing where to start or what to look for can be challenging, especially if you’re a newbie. However, with the following tips, you can make a more informed choice:

- Look for a service that specializes in the type of 3D Printing you need

- Check out reviews and ratings

- Consider the materials offered

- Look at pricing and turnaround times

- Evaluate customer service and support